Image Analysis Software- Caliper Pro

20000.00 - 80000.00 INR

Product Details:

- Interface Type Graphical User Interface (GUI)

- Compatible System Windows 7/8/10

- Capacity (Person) Single user or multi-user with license

- Usage Industrial and laboratory use

- Security Features Password protection and user access control

- Support System Windows operating systems

- Language Support English

- Click to View more

X

Image Analysis Software- Caliper Pro Price And Quantity

- 20000.00 - 80000.00 INR

- 1 Unit

Image Analysis Software- Caliper Pro Product Specifications

- Graphical User Interface (GUI)

- Image analysis and measurement

- English

- Image Analysis Software

- Password protection and user access control

- Windows operating systems

- Industrial and laboratory use

- Windows 7/8/10

- Single user or multi-user with license

Image Analysis Software- Caliper Pro Trade Information

- Telegraphic Transfer (T/T), Cheque

- 1 Unit Per Day

- 2-3 Days

- All India

Product Description

We are passionately engaged in providing our clients highly reliable Metallurgy Software that can be used in steel plants, metal forging industry, oil & gas industry and where metallurgical microscopes are used. Our professionals develop this software keeping in mind the exact requirements of clients. Also, our professionals thoroughly do the testing to make it bugs free prior to delivering this to clients. This Metallurgy Software is very useful for educational institutions and all material science technocrats and metallurgist.

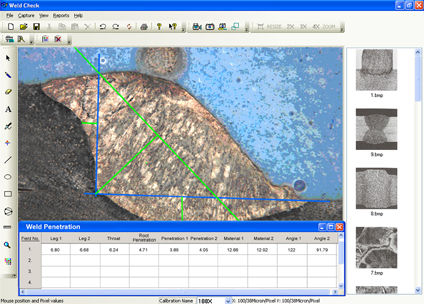

Image analysis - Caliper Pro

Application Program are set in the simplest way without compromising accuracy so that inexperienced operator can also make analysis with a minimum of training. Our current portfolio of metallurgy solutions are Nodules analysis, Coating Thickness Measurement, Depth of Width Measurement of Decarburization, Phase percentage with display by colored overlays, Grain Size No., Porosity Analysis, Graphite Flakes Measurement, Non-Metallic Inclusion Rating, Particle Size and Volume Percentage with lot make software complete. Generated reports can be saved or printed with images, Histogram, Data Overlays colors and various other related information.

IMAGE EDITING

VIEW

- Cut, Copy, and Paste.

- Selected copy by free hand AOL controlled by four arrow keys available on keyboard or mouse with zoom preview.

- Crop, duplicate, restore

- Resize

- Compression

- Conversion to other format BMP, JPG, TIF, PNG, GIF & PSD

- Flood fill or spray with selected color at selected portion.

- Grid creation; 5X5, 10X10 & 100X100 grids (or cells).

- Drawing tool curve, line, square, and circle with node control and provision to change color & thickness of the line.

- Write text in any color or font.

- Pointer to place on an object in either of four directions with provision to change its color & thickness.

- Eraser works only on line, arrow or on any drawing tool.(not on original image)

- Camera Lucida

- Montage feature to merge stored image together. Useful to Merge different focuses of same image.

- Zoom in/out

- Zoomed preview

- Rotation at 90, 180,270 or custom

- Image flipping; horizontal or vertical axis

- Intensity histogram.

- Image Information

- Redo/Undo on all operations.

IMAGE PROCESSING

- Background subtraction and contrast enhancement of color or grayscale images

- Arithmatic image functions (Boolean Math; Add, AND, OR, XOR, DIFF, MIN, MAX, +, -, /, *, And Simple).

- Invert, Brightness, Contrast, Hue, Saturation, Blur, Noise Remove, Emboss, Engrave, Gamma R, Gamma G, Gamma B, Yellow, Magenta, Cyan, Mosaic, Smooth, Desaturation, Pseudo Color, Colorize, Oilify, Despeckle, Posterize.

- High Boost, High Spatial, Low Pass Spatial, Ranking (Max, Med, Min), Point detection, Line detection, Homogeneity

- Laplacing, Sobel, Krisch, Prewitt Gradient, Shift & Difference, Combine, Contrast Base, Quick, Range And Variance.

- Skeletonizing, Pruning, SKIZ, Histogram Equalization, Histogram Smoothing, Histogram Peak, Histogram Valley, Segmentation by Over/Under and Quantized, Contoring, Dilation / Erosion on Binary, Gray & colored Images, Opening/ Closing on Gray & Binary Images, Special Opening/Closing, Split/Combine of RGB, YUV, YIQ, XYZ, & HSL, Changing any Image to 1, 4, 8 & 24 bits, Medial Axis. Transformation, Halftone.

- Image Addition, Image Average, Image Subtraction, Image Multiplication.

- Spatial calibration

- Line measurements for Distance, Length, Width, Perimeter, Angle, Three Point Radius.

- Area by enclosed line controlled by four arrow keys available on keyboard arrows with zoomed preview.

- Identification of objects in an image, count them, obtain several features measurements. Objects identification by user or automatically. User defined classification on basis of size or intensity.

- Manual, Auto bright and Auto dark methods to identify intensity range defined object to be measured. Various calculation & measurements available for selected Particle are; Dimensions, Area, Perimeter, Feret Length, Min/Max Radius, Thread Length, Thread Width, Fibre Length, Fibre Width.

- Roundness, Shape, Orientation, Elongation, Equal Circular Diameter, Equal Sphere Volume.

- Centroid X, Centroid Y, Major X1, Major Y1, Minor X1, Minor Y1, Major X2, Major Y, Major X2, Minor Y2, Box X1, Box X2, Box Y, Box Y2 & Box Area.

- Measure area fraction & volume fraction. Identify multiple phases within Microstructure. Also delineate phases from the histogram as per ASTM Standard E562 & E1245.

- MEASURE Nodularity as per ASTM 247 standard. The Nodules & Flakes are separated on the basis of its shape and aspect radio.

- The detail measurement of each microstructure is available for further analysis.

- The processed image displays non-Nodules in different color.

- The Nodules can be classify by its range on the basis of its size & shape.

- They are recognized on the basis of its intensity as per ASTM B-276 standard. The measurement of each pore is displayed. The processed image displays pores in Red color.

- This application rapidly measures the thickness or width of a coating at multiple positions along a sample as per ASTM B487 standard.

- Tabulated results available for min/max and mean of width measured at various points of sample cross section.

- Measured depth or width of decarburisation occurs as per ASTM 1077 standard.

- The module analyse Grain image and measure the Grain no. & Grain size using ASTM E 112 method.

- The options for measurement available are 1. Manual Trace, 2. Popular Comparison Method, 3. Quick single Grain measurement, 4. ALA method, 5. Interception method.

- Various filters to make user defined templates. Grain boundary repair mathematical function.

- Non-Metallic Inclusion

- Measure inclusions and report ASTM E-45, E-1245 numbers, cumulative length, width ratio.

- Graphite Flakes

- Graphite Flakes length, width, distribution and percentage as per ASTM A-247-67

- Three options: Direct printout with original image processed Image & Tabular results

- Export to MS Office or Excel for further modification.

Versatile Image Format Handling

Caliper Pro accommodates a wide array of image formats including BMP, JPG, PNG, TIFF, and GIF, ensuring users can easily import and analyze images from various sources. This flexibility streamlines workflows in industries and labs dealing with diverse imaging equipment and file types.

Precision Measurement Tools

Users benefit from an extensive toolbox for accurate measurement of length, area, angle, perimeter, and counting. Calibration support guarantees reliable results, making Caliper Pro suitable for applications demanding rigorous analytical standards.

Effortless Reporting and Data Export

Customizable report templates and seamless export options (CSV, Excel, PDF) enable efficient documentation and sharing of results. Generate professional reports to meet project, regulatory, or client requirements directly within the software.

FAQs of Image Analysis Software- Caliper Pro:

Q: How does Caliper Pro facilitate image analysis and measurement?

A: Caliper Pro comes equipped with a range of measurement toolslength, area, angle, perimeter, and countcoupled with calibration support. The intuitive GUI allows users to quickly load images, perform measurements, and extract quantitative data for comprehensive analysis.Q: What is the process for installing Caliper Pro on a compatible Windows system?

A: Installation is straightforward with a guided setup and a detailed user manual. Simply ensure your Windows PC meets the minimum system requirements (Windows 7/8/10, 2GB RAM, 500MB disk space), then follow the on-screen instructions to complete the installation.Q: When can users access technical support or online updates for the software?

A: Technical support and online updates are available whenever required. Registered users can access updates and assistance through the support portal to ensure the software always stays current and runs reliably.Q: Where can Caliper Pro be used, and what applications does it support?

A: Caliper Pro is designed for use in both industrial and laboratory environments within India or globally. It is ideal for any application requiring image-based measurements and analysis, such as quality control, research, and documentation.Q: What are the benefits of Caliper Pros ability to export data and generate reports?

A: Users have the advantage of producing customizable reports and exporting data in various formats (CSV, Excel, PDF). This feature streamlines record-keeping, sharing findings, and conforming to regulatory or project-based documentation requirements.Q: How does the software ensure the security of user data and control access?

A: Security features such as password protection and user access controls are built-in, ensuring that sensitive data and analytical results remain secure and accessible only to authorized personnel.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Biological Image Analysis Software' category

|

DEWINTER OPTICAL INC.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |